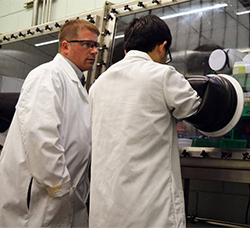

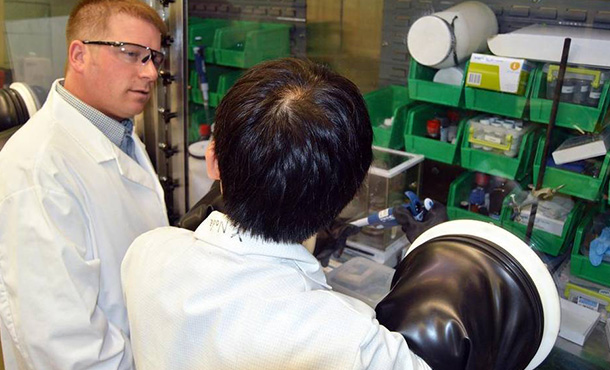

Penn State professor Robert Rioux, left, works alongside postdoctoral researcher, Yu Noda, in his laboratory in the Department of Chemical Engineering. The duo are testing the reaction of engineered catalysts to determine possible outcomes.

Chemical catalysts can help achieve sustainable goals

8/23/2015

Chances are, you didn’t give much thought to catalysts this morning as you consumed your multivitamin, filled your reusable plastic water bottle or headed out the door to start your vehicle. Astonishingly enough, however, all of these products are shaped by catalysts, which are involved in more than 90 percent of all domestic manufacturing processes in the chemical industry.

Catalysts, by definition, are substances that lower the energy barriers of chemical reactions and lead to an increase in the rate at which new substances are created. They are not consumed in the reactions, however, and that enables them to be reused over and over again. Catalysts are used to transform raw chemical ingredients into petroleum products, pharmaceuticals, synthetic plastics and rubber and food products — as well as to control vehicle and industry emissions.

Developing and improving new catalysts is a science that involves chemical intuition, experimentation and examination. It is also the research focus of Robert Rioux’s laboratory group in the department of chemical engineering at Penn State.

“Catalysts are possibly the most important solid materials in the chemical industry,” said Rioux, Friedrich G. Helfferich associate professor of chemical engineering. “Their objective is to reduce energy consumption, reduce the production of byproducts and waste and to help achieve sustainable goals while maintaining an economically positive process.”

Rioux’s research group works experimentally to discover and test new catalysts to achieve these means. The team works closely with theoretical counterparts to hypothesize and design new agents and test their viability.

A major focus of Rioux’s lab is exploring how to replace the expensive precious metals typically used in catalysts — gold, platinum, rhodium and others — with more abundant elements such as nickel, iron and cobalt. The effort aims to both reduce domestic manufacturing costs and protect environmental resources.

“The challenges in replacing precious metals are immense but the effort is necessary,” Rioux said. “As our reserves of precious metals dwindle there is an emphasis in both the fundamental and applied realms of the discipline to develop new materials that utilize base metals. In some instances, it completely changes the molecular nature by which the catalytic reaction proceeds.”

One of the most discernible examples of a precious metal catalyst can be found between the engine and exhaust system of your vehicle — the catalytic converter. Catalytic converters were first introduced in the 1970s when smog was recognized as a serious problem in urban areas. Since that time, they have been mandated in all vehicles in the U.S.

Catalytic converters control emissions by converting toxic pollutants into less harmful or even inert matter. The issue with these devices, however, is that they achieve their intended function by relying on three precious metals: platinum, palladium and rhodium.

“We are running out of those materials.” Rioux warned. “While the amount of metal used in a converter is small, you must multiply that amount by the number of new cars we manufacture each year — and it’s a really pressing issue. We need to figure out how to further reduce the amount of these metals used or completely replace them.”

Research into catalysts transcends multiple boundaries. In fact, catalysts can be found almost everywhere. They are used in the production of plastics, food, pharmaceuticals and even in our own bodies in the form of enzymes.

“You are who you are because of biological catalysts called enzymes,” Rioux explained. “They are the most exquisite entity in that they have the ability to do one thing and one thing only when presented with a multitude of options within the body. This is referred to as selectivity, and enzymes are the most selective catalysts known. They have an efficiency that is typically greater than anything we can make inside the laboratory. This is why the catalysts that reside inside our body inspire those who attempt to design and create synthetic chemical catalysts.”

Recently, Rioux’s group discovered a catalyst that has allowed them to produce a bio-derived carbocyclic acid that acts as a superabsorbent. The new superabsorbent could one day be used in the manufacturing of diapers. What started out as a side project for Rioux’s group quickly developed into something more.

“The catalyst we discovered is more efficient and affordable than anything currently available on the market,” Rioux said.

The new catalyst is currently being piloted to test its long-term performance. If successful, Rioux and his group will work with a catalyst manufacturer to scale up the synthesis of the catalyst for large-scale production.

Discovering a new catalyst suited for industry is not always easy, however.

Not only does the catalyst need to be more efficient than what is currently obtainable, it must also provide a cost savings to the manufacturer and be easily replicated at a large scale. Aligning all of these variables can be a monumental challenge.

While not every catalyst experiment is a success, Rioux cited the academic arena as a place where students can learn from their failures as well as their successes.

“When we find something that is unexpected we push really hard to find the origins, and so, the benefit of academia compared to industry, as long as we can secure the financial backing, is that we have the ability to delve into the details at an atomic or molecular level as we try to understand why the outcome was unexpected. That helps us succeed in future experiments.”

In 2015, Rioux was awarded funding from National Science Foundation, the Department of Energy, the Air Force Office of Scientific Research and a number of industry sponsors. He was also awarded the Penn State Engineering Alumni Society’s Outstanding Research Award.

To expand his knowledge, Rioux will take a sabbatical at the department of chemistry at Utrecht University in the Netherlands later this year. There, he will work in the laboratory of renowned chemist Bert Weckhuysen. At Utrecht, Rioux aims to further develop single particle and molecule techniques as they apply to understanding heterogeneous catalysts used to upgrade petroleum to gasoline.